Automotive Wiring Harness

Custom Molex Microfit 2x3 Receptacle Connector To OBD2 Connector Extension Cable

- Product ID:Automotive Wiring Harness

- Skype:+86 137 5185 9234

- Phone: +86 137 5185 9234

- Tel: +86 137 5185 9234

- Email: sales2@gh-electronics.com

- Time: 2020-03-02

-

INQUIRY

|

Place of Origin: Guangdong, China |

Brand Name: GuangHui Electronics / OEM |

|

Cable length: Optional |

Application: Automotive.Auto.Motocycle |

|

Jacket: PVC |

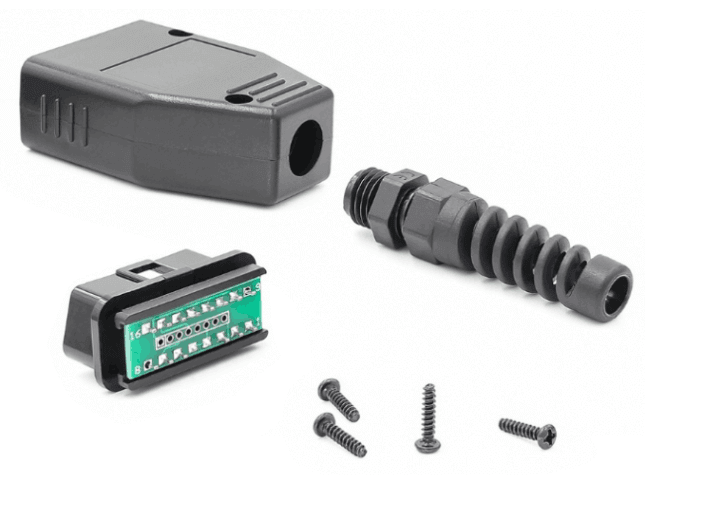

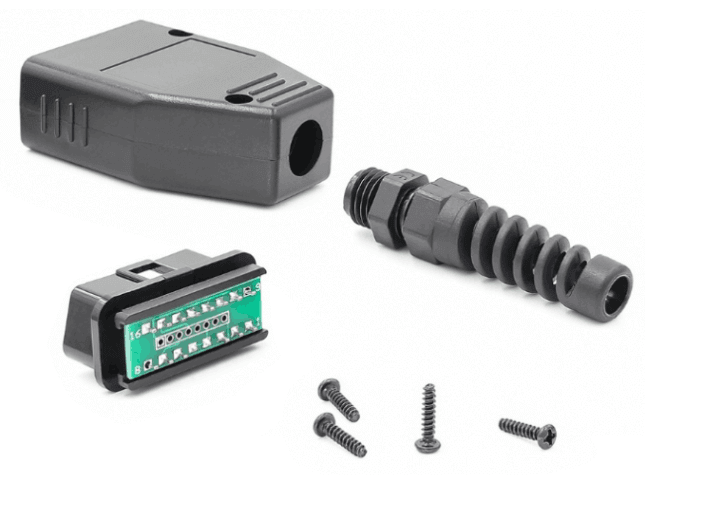

Connector1: OBD2, OBD ii |

|

Connector2: 6PIN PH2.54MM PN:430250600 MOLEX |

Cable Spec: UL2464 6C*20AWG UNSH;PVC;BLACK;OD:6.0MM |

|

Color: Black / Optional |

All cable will be 100% test before delivery |

|

Certification: RoHS, CE, TS16949 |

Insulation Material: Rubber, Silica gel, PE, PVC, Teflon or as per customer request |

|

Samples: available |

MOQ: 500PCS |

ELECTRICAL TESTING:

1. 100% OPEN, SHORT, MISS WIRE & INTERMITANCE TEST;

2. CONDUCTOR RESISTANCE 3 ohm MAX;

3. INSULATION RESISTANCE: 10M ohm Min/300V DC, 10ms;

With the increasing degree of economic globalization and automobile internationalization, the OBD Ⅱ system will be more and more widely implemented and applied as the basis for driving and emission diagnosis. The OBD Ⅱ program makes automobile fault diagnosis simple and uniform, and maintenance personnel do not need to learn new systems from each manufacturer.

The OBD system will monitor whether the car's exhaust exceeds the limit from the engine's operating condition at any time, and will immediately issue a warning if it exceeds the limit. When the system fails, the fault (MIL) light or check engine (Check Engine) warning light is on, and the powertrain control module (PCM) stores the fault information in the memory, and the fault code can be read from the PCM through a certain program . According to the prompt of the fault code, the maintenance personnel can quickly and accurately determine the nature and location of the fault.

OBD monitors the engine, catalytic converter, particulate trap, oxygen sensor, emission control system, fuel system, EGR and other systems and components in real time. Then connect to the ECU [electronic control unit, which can detect and analyze the function of emission-related failures] through different emission-related component information. When an emission failure occurs, the ECU records the failure information and related codes, and sends it out through the failure light Warning, inform the driver. ECU guarantees the access and processing of fault information through standard data interface.