The Vital Veins of Modern Technology: A Guide to Wire Harnesses

Introduction

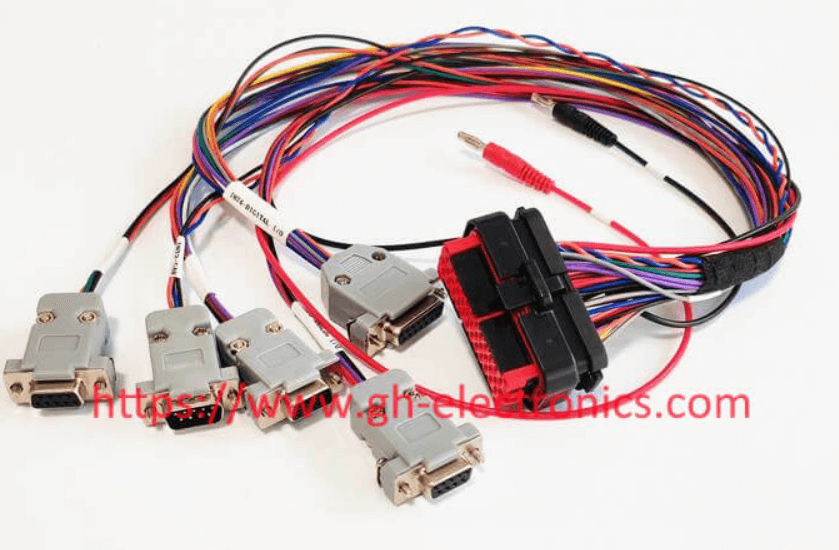

Invisible yet indispensable,

wire harnesses are the central nervous system of nearly every piece of modern machinery. From automobiles and aircraft to medical devices and smart home appliances, these organized assemblies of wires, terminals, and connectors ensure power and data flow reliably. This article explores their evolution, demystifies the custom manufacturing process, and provides a strategic guide to sourcing high-quality harnesses from China, the world's manufacturing hub.

From chaotic wiring to structured harnesses – the key to reliability and efficiency.

Part 1: A Historical Journey – The Evolution of the Wire Harness

The story of the wire harness mirrors the story of electrification and technological integration.

. Early 20th Century – The Birth of Complexity: In the earliest automobiles and radios, wiring was simple, sparse, and hand-tied. As electrical components (headlights, ignition, radios) proliferated in the 1920s-1930s, the need arose to bundle wires together for organization, protection, and easier installation. The first true harnesses were born, often wrapped in fabric tape.

. Post-WWII Boom – Standardization and Scale: The automotive and aerospace booms demanded mass production. The invention of durable insulating materials like PVC (Polyvinyl Chloride) in the mid-20th century was a revolution. Harnesses became more standardized, and semi-automated processes for cutting and stripping wires began to emerge.

. 1970s-1990s – The Rise of Automation and Complexity: With the introduction of computer systems (ECUs), airbags, and advanced audio systems, vehicle electrical architectures exploded in complexity. Manual assembly became a bottleneck. This era saw the adoption of computer-aided design (CAD) for layout and the first generation of fully automated wire processing machines (cutting, stripping, crimping), drastically improving consistency and speed.

. 21st Century – Intelligence, Lightweighting, and High-Speed Data: Today's trends are transformative:

>High-Voltage Harnesses: Essential for electric vehicles, requiring specialized materials for safety and high-current carrying capacity.

>High-Speed Data Cables: Shielded cables (like coaxial or twisted pair) for infotainment, ADAS (Advanced Driver-Assistance Systems), and in-car networks.

>Lightweight Materials: Aluminum wires and thinner insulation to reduce weight and improve fuel efficiency.

>Automation & Traceability: Fully automated guided assembly benches, robotic crimping, and barcode tracking for every component ensure zero-defect goals and full traceability from source to finished product.

The evolution of wire harness technology, driven by industry demands.

Part 2: Inside the Factory – The Custom Wire Harness Manufacturing Process

Creating a custom harness is a meticulous, multi-stage process that blends engineering with precise craftsmanship.

1. Design & Engineering: It all starts with a schematic or list of requirements. Engineers use specialized CAD software (e.g., CATIA, AutoCAD Electrical) to design the routing, connector types, wire gauges, and protective coverings. A virtual prototype is tested for electrical integrity and fit.

2. Prototyping: A physical sample is built by technicians on a manual or semi-automatic bench. This prototype is rigorously tested for electrical continuity, insulation resistance, pull strength, and fit-and-function in the intended device. This stage is crucial for validation before mass production.

3. Production Planning & Kitting: Once approved, the manufacturing plan is finalized. All components—wires of specified colors and lengths, connectors, terminals, sleeves, conduits (like braided loom or corrugated tubing)—are sourced and kitted for each harness variant.

4. Assembly Process:

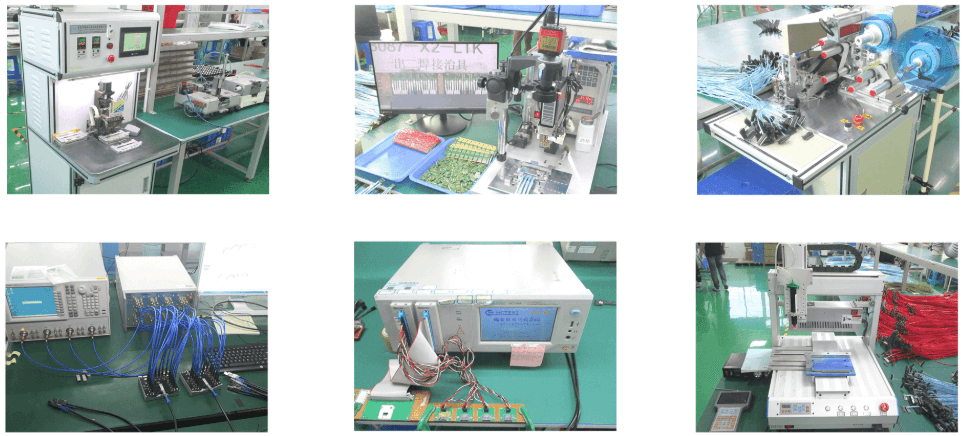

>Cutting & Stripping: Wires are cut to precise lengths, and insulation is stripped from ends automatically.

>Termination: Terminals are crimped onto wire ends using calibrated machines. Quality is checked via pull-force tests and often monitored by vision systems.

>Sub-Assembly: Smaller sections of the harness are pre-assembled on pin boards or jigs—full-scale diagrams that guide the layout.

>Final Assembly & Binding: Wires are routed together on the assembly board and bound with ties, tape, or loom. Connectors are mated.

>Testing & Quality Control: Every single harness must pass final tests. This includes a 100% continuity test (checking for opens/shorts) and often a hi-pot (dielectric withstand) test. Advanced harnesses may undergo functional tests simulating real-world signals.

>Packaging & Delivery: Harnesses are carefully packaged to prevent bending or connector damage during shipping, often on dedicated racks or in anti-static bags.

The end-to-end custom wire harness manufacturing workflow.

Part 3: A Buyer’s Guide – How to Select a Reliable Wire Harness Supplier in China

China hosts a vast spectrum of suppliers, from small workshops to global, vertically integrated giants. Choosing the right partner is critical.

1. Define Your Requirements Precisely:

Prepare a clear specification sheet: technical drawings, 3D models, wire/connector specs, acceptance test standards, target volume, and IP/weatherproofing ratings. Clarity prevents misunderstandings and filters out incapable suppliers.

2. Critical Supplier Evaluation Criteria:

. Technical & Engineering Capability: Do they have in-house CAD design and DFM (Design for Manufacturability) support? Can they help optimize your design? This is a sign of a value-added partner.

. Quality Certifications & Systems: Mandatory certifications include IATF 16949 (automotive quality standard) or ISO 9001. Look for ISO 14001 for environmental management. Ask about their QC process, testing equipment, and how they handle non-conforming products.

. Manufacturing Capabilities & Automation: Assess their machinery. Do they have automated cutting/stripping/crimping machines? For high-volume orders, automated assembly benches are key for consistency. Check their capacity to avoid bottlenecks.

. Supply Chain & Material Control: A good supplier has robust control over their component sources, using reputable brand-name (TE, Molex, Sumitomo) or certified equivalent materials. They should provide material certification upon request.

. Sample Process: Always request a prototype or pre-production sample. Evaluate its quality, workmanship, and documentation. Pay for this sample—it’s a vital investment.

. Communication & Transparency: Are they responsive? Do they understand your language (have English-speaking staff/engineers)? Will they provide regular production updates? Transparency on issues is more important than perfection.

3. Due Diligence & Factory Audit:

. Virtual Audit: Request a live video tour of the factory floor, QC lab, and warehouse.

. On-Site Audit (Gold Standard): For large projects, visiting in person is invaluable. Observe the production environment, worker skill, and quality culture firsthand.

. Check References: Ask for client references in your industry or region.

Red Flags to Avoid:

. Unusually low quotes without detailed breakdowns.

. Reluctance to share company details or facility videos.

. No clear quality control process or certifications.

. Poor communication and slow responses.

Conclusion

The humble wire harness has evolved from simple bundles to highly engineered, intelligent systems. Understanding its history and complex manufacturing process empowers buyers. When sourcing from China, a strategic, diligence-focused approach—prioritizing technical capability, proven quality systems, and transparent communication over price alone—is the surest path to finding a supplier that will become a reliable partner in bringing your innovative products to life.

Dongguan Guanghui Electronic Technology Co., Ltd. is a high-tech enterprise specializing in wire harnesses and cable assemblies, with more than 19 years of R&D experience. We can provide better economic solutions and innovative wiring harnesses for many industries, such as automotive, machinery, medical, electrical, communications and other cable assemblies. With the support of R&D engineering, we focus on turnkey solutions. Support OEM/ODM.

We have a complete and advanced APQP R&D system, and all processes follow the IPC620 standard. Our advantage is to quickly provide high-quality solutions and professional services for production enterprises. Welcome to visit our factory!