Beyond the Connector: The Strategic Value of a Custom Molex Cable Assembly Manufacturer

In the intricate ecosystems of modern electronics, the cable is often the unsung hero—or the critical point of failure. While Molex connectors are renowned for their reliability and ubiquity across industries,

a true competitive advantage lies not just in the component, but in its seamless, optimized integration. This is where partnering with a specialized

Custom Molex Cable Assembly Manufacturer transitions from a procurement decision to a strategic engineering partnership.

The Limitations of Off-the-Shelf and the Imperative for Customization

Standard cables represent a compromise. They are designed for general use, which often means they are not ideal for any specific use. In demanding applications, this compromise can manifest as:

. Excess Bulk: Unnecessary cable length or oversized jackets wasting space in compact designs.

. Performance Gaps: Inadequate current rating, insufficient shielding against EMI/RFI, or poor flexibility for dynamic applications.

. Reliability Risks: Connectors that are under-specced for vibration, temperature cycles, or mating cycles, leading to field failures.

A custom manufacturer eliminates these compromises by engineering the entire interconnect system—wire, terminal, housing, and strain relief—as a unified solution tailored to your exact operational environment.

The In-Depth Process: From Concept to Certified Assembly

A professional manufacturer’s workflow is a testament to precision and quality assurance:

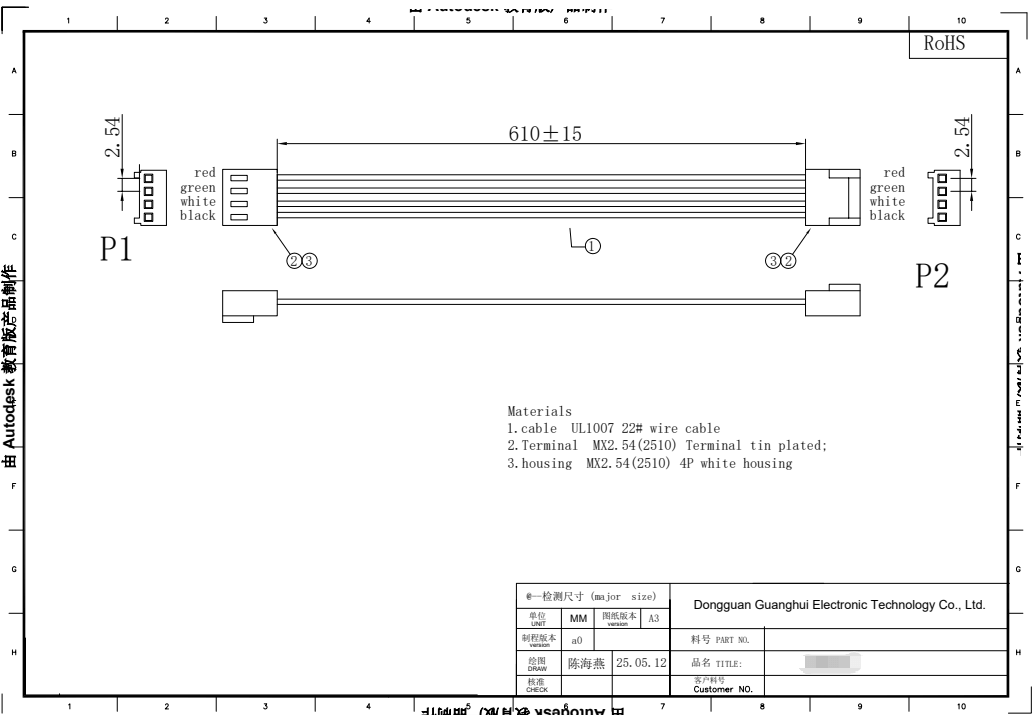

1. Collaborative Design & Specification: Engineers collaborate with your team to select the optimal Molex series (e.g., Mini-Fit Plus for high power, PICOBLADE for ultra-fine pitch, MX150 for sealed automotive applications). They specify wire gauge, stranding, shielding (braid vs. foil), jacket material (PVC, PUR, TPE), and define critical tests.

2. Precision Manufacturing:

> Cutting & Stripping: Automated machines ensure exact length and clean, consistent strip lengths without nicking conductors.

> The Art of Crimping: This is the core. Computer-controlled crimp presses apply the exact force and profile to create a gas-tight connection between the Molex terminal and wire. This is verified by pull-force testing and cross-section analysis.

> Housing Assembly: Terminals are accurately loaded into the connector housing, with poka-yoke (error-proofing) techniques to prevent mis-insertion.

> Overmolding & Strain Relief: For extreme durability, custom overmolds are designed to provide robust strain relief, sealing, and brand identification.

3. Rigorous Validation & Compliance: Every batch undergoes 100% electrical testing (continuity, hipot). Compliance with standards like UL, CSA, RoHS, and REACH is documented, and assemblies can be validated to specific IPC/WHMA-A-620 workmanship standards for cable and wire harness assemblies.

Tangible Benefits that Impact Your Bottom Line

. Enhanced Product Reliability & Safety: Custom assemblies are built to withstand your specific environmental stresses (heat, cold, chemicals, flexing), directly reducing warranty claims and safety risks.

. Optimized System Performance: Perfectly matched impedance, shielding, and current capacity ensure signal integrity and power delivery, maximizing the performance of your end product.

. Streamlined Assembly & Lower Total Cost: Harnesses that arrive pre-tested and ready to plug-in drastically reduce your production labor, eliminate on-site crimping errors, and accelerate time-to-market. While unit cost may be higher, the total cost of ownership plummets.

. Scalability and Supply Chain Stability: A strong manufacturer acts as an extension of your supply chain, managing component procurement, inventory, and scaling production from prototype phases to full volume runs seamlessly.

Who Needs This Partnership? Key Industries

. Medical Device Manufacturers: Where reliability, sterilizability, and regulatory compliance (ISO 13485) are paramount.

. Automotive & Electric Vehicle (EV) Suppliers: Requiring solutions that meet strict USCAR and LV214 standards for vibration, temperature, and seal performance.

. Industrial Automation & Robotics: Demanding cables for continuous flex, torsional stress, and noise immunity in harsh factory environments.

. Aerospace & Defense: Where extreme lightweight, high-reliability, and mission-critical performance are non-negotiable.

. High-End Telecommunications & Computing: For precision internal cabling in servers and networking gear where airflow and signal speed are crucial.

In a world where connectivity defines functionality, the cable is your product's central nervous system. Choosing to collaborate with a specialized Custom Molex Cable Assembly Manufacturer is an investment in product integrity, performance, and market success. It’s the decision to build not just with parts, but with purpose-engineered solutions.

Ready to engineer reliability into every connection?

Contact our team of experts to discuss how a tailored Molex cable assembly partnership can power your next innovation.