The Ultimate Guide to Custom Automotive Wiring Harnesses: Design, Benefits & Installation

Introduction: Why Standard Harnesses Often Fall Short

In the world of automotive customization, restoration, and high-performance builds, factory wiring harnesses frequently become the limiting factor. Whether you're installing a modern EFI system in a classic muscle car, adding extensive aftermarket electronics, or building a race car from the ground up, a custom automotive wiring harness provides the tailored solution that OEM setups simply cannot offer. This comprehensive guide explores everything you need to know about custom wiring solutions for your vehicle.

What Is a Custom Automotive Wiring Harness?

Unlike mass-produced factory harnesses designed for specific year-make-model configurations, a

custom automotive wiring harness is engineered and built to exact specifications for a particular vehicle and application. It's not merely a modified OEM harness but a completely bespoke electrical system designed from scratch to meet unique requirements.

Key Characteristics:

. Vehicle-Specific Design: Tailored to your exact chassis, engine, and component layout

. Application-Oriented: Built for your specific use case (street, show, race, off-road)

. Future-Proof Architecture: Designed with expandability for future modifications

. Quality-Centric Components: Uses superior materials than typical factory harnesses

When Do You Need a Custom Wiring Harness?

1. Vehicle Restorations & Modifications

. Classic Car Restorations: Factory harnesses are often deteriorated beyond repair

. Engine Swaps: Installing a modern engine into an older chassis

. Frame-Off Restorations: Building from bare metal with all-new components

. Restomods: Blending vintage aesthetics with modern technology

2. Performance & Competition Applications

. Race Cars: Extreme environments demand robust, simplified wiring

. Drag Racing: Weight reduction and reliability are paramount

. Off-Road Vehicles: Enhanced durability against vibration and elements

. Track-Day Cars: Improved serviceability and safety systems

3. Advanced Electronic Integration

. Modern Conveniences in Classic Cars: Adding power windows, A/C, security systems

. Advanced Audio/Video Systems: High-power requirements and signal integrity

. Multiple ECU Setups: Standalone engine management, transmission controllers

. Data Acquisition Systems: Sensors, cameras, and telemetry equipment

The Benefits of Going Custom: Beyond Just Wiring

Enhanced Reliability & Safety

. Proper Circuit Protection: Each circuit individually fused based on actual load

. Correct Wire Gauges: Eliminates voltage drop and overheating risks

. High-Quality Terminations: Professional crimping versus factory solder joints

. Improved Grounding: Dedicated ground points with proper sizing

Simplified Maintenance & Troubleshooting

. Logical Circuit Organization: Systems grouped intuitively (lighting, ignition, accessories)

. Clear Documentation: Comprehensive schematics and wire identification

. Service-Friendly Design: Connectors placed in accessible locations

. Modular Construction: Sub-harnesses for easy component removal

Performance Advantages

. Weight Reduction: Eliminates unnecessary circuits and uses lighter materials

. Electrical Efficiency: Optimized wire runs reduce resistance

. Signal Integrity: Separated power and signal wiring minimizes interference

. Expandability: Built-in spare circuits and connectors for future upgrades

Aesthetic & Professional Results

. Clean Installation: Wires routed neatly without excess bulk

. Professional Appearance: Color-coded wiring with matching loom

. Integration Quality: Looks like factory (or better) when completed

. Resale Value: Documented custom wiring can increase vehicle value

The Custom Wiring Harness Design Process: Step-by-Step

Phase 1: Initial Consultation & Planning

1. Vehicle Assessment: Current electrical state, intended use, and goals

2. Component Inventory: List all electrical devices and their specifications

3. Power Analysis: Calculate current draws for proper wire sizing

4. Layout Planning: Determine optimal routing and connector placement

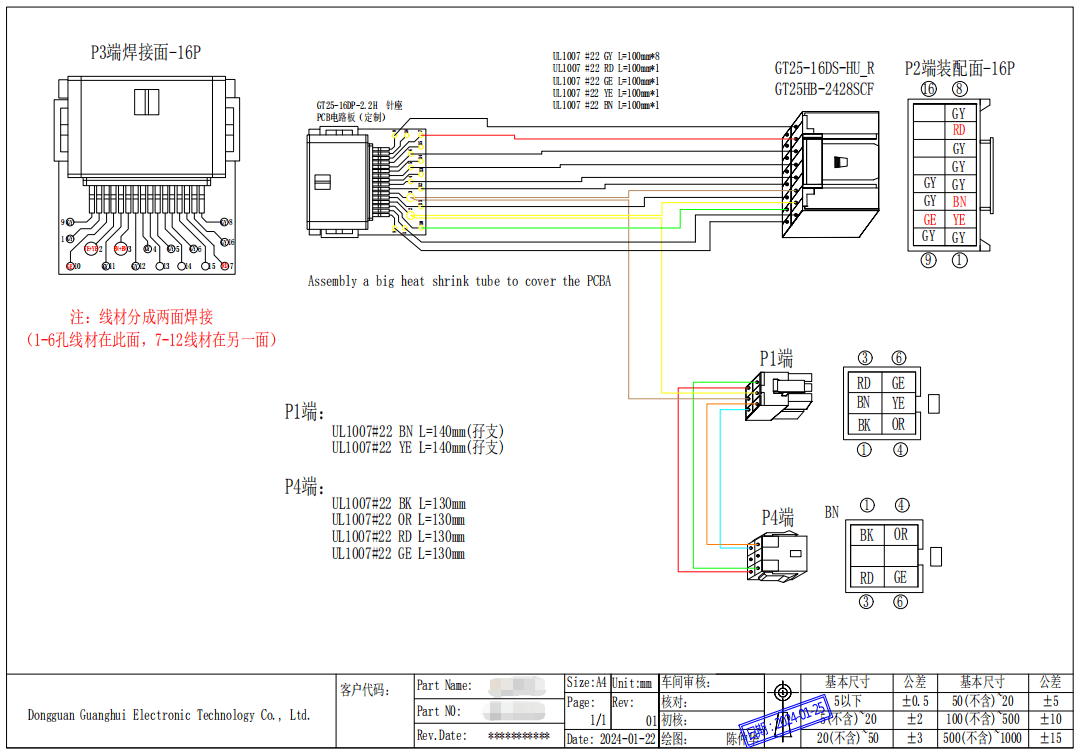

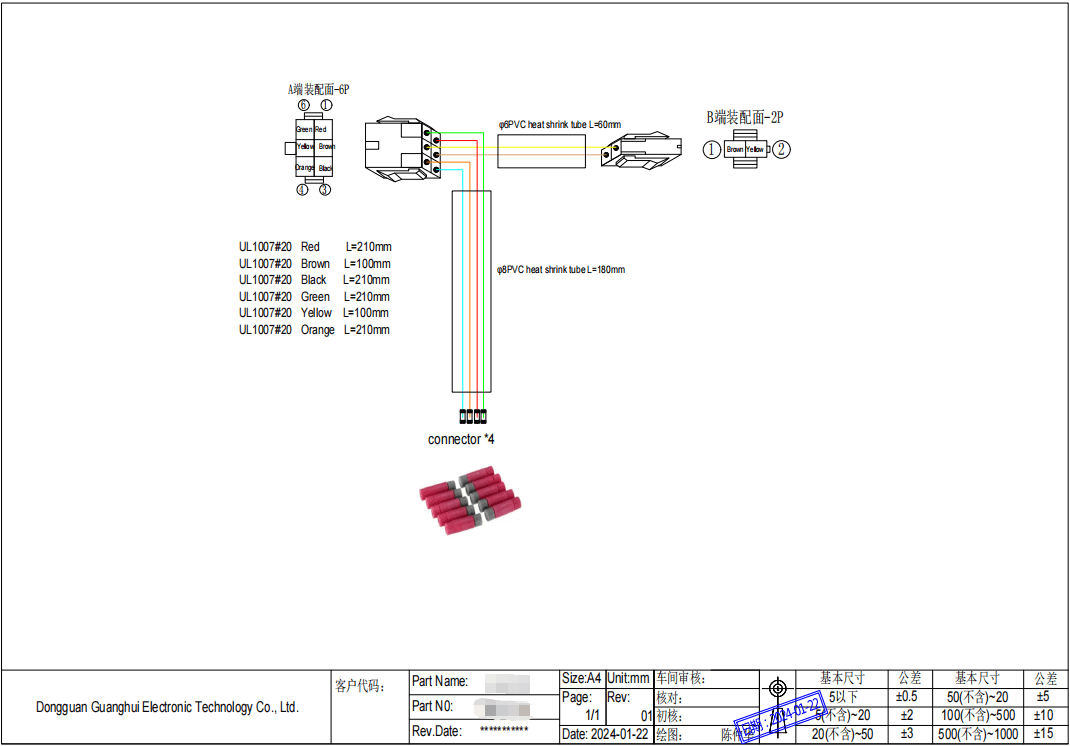

Phase 2: Schematic Development

1. Circuit Design: Create logical electrical diagrams

2. Connector Selection: Choose appropriate sealed or unsealed connectors

3. Wire Specification: Select gauges, insulation types, and colors

4. Protection Strategy: Plan fuse panels, relays, and circuit breakers

Phase 3: Harness Fabrication

1. Wire Cutting & Stripping: Precision measurements and preparation

2. Termination: Professional crimping with quality tools

3. Assembly: Building sub-harnesses and main harness sections

4. Protection Application: Adding loom, conduit, and heat shielding

5. Labeling: Clear identification on every wire and connector

Phase 4: Testing & Quality Control

1. Continuity Testing: Verify every connection point-to-point

2. Short Circuit Testing: Ensure no unintended connections

3. Load Testing: Verify performance under actual electrical loads

4. Documentation: Finalize schematics, connection guides, and BOM

Key Components of a Quality Custom Harness

1. Wire & Cable Selection

. Primary Wire: GPT (general purpose thermoplastic) or cross-linked polyethylene

. Battery Cable: Fine-strand welding cable for flexibility

. Shielded Cable: For sensors and audio signals

. High-Temp Wire: For engine bay and exhaust proximity

2. Connectors & Terminals

. Sealed Connectors: Deutsch, TE Connectivity, or Molex for harsh environments

. Unsealed Connectors: Packard/Delphi style for interior applications

. Terminals: Copper alloy with proper plating (tin or gold)

. Tools: Manufacturer-specific crimping tools for perfect connections

3. Protection & Routing

. Loom Types: Braided sleeve, convoluted tubing, or expandable mesh

. Heat Protection: Fiberglass or ceramic sleeving near hot components

. Mounting Hardware: Adel clamps, P-clips, and nylon ties

. Strain Relief: Grommets and boots at penetration points

4. Distribution & Protection Centers

. Fuse Panels: ATO/ATC, mini, or maxi fuses with sufficient spare positions

. Relay Centers: Properly rated for continuous duty if needed

. Bus Bars: For clean power and ground distribution

. Circuit Breakers: For circuits with intermittent high loads

Conclusion: Is a Custom Wiring Harness Right for Your Project?

A custom automotive wiring harness represents more than just wires and connectors—it's the foundation of a reliable, safe, and capable vehicle electrical system. While the upfront investment is greater than repairing or modifying a factory harness, the long-term benefits in reliability, serviceability, and peace of mind are substantial.

Whether you're building a show-winning restoration, a track-dominating race car, or simply want the most reliable daily driver possible, a properly designed custom wiring harness delivers electrical performance that matches your vehicle's mechanical capabilities.

Next Steps:

1. Evaluate your needs and project complexity

2. Gather specifications for all electrical components

3. Consult with professionals if outside your comfort zone

4. Budget appropriately for quality materials and labor

5. Plan the timeline accounting for design, fabrication, and installation

The road to a perfectly wired vehicle begins with a single connection. Make that connection count with a harness designed specifically for your automotive vision.

We have a complete and advanced APQP R&D system, and all processes follow the IPC620 standard. Our advantage is to quickly provide high-quality solutions and professional services for production enterprises.Welcome to visit our factory in China!